What is a Vertical Lift machine?

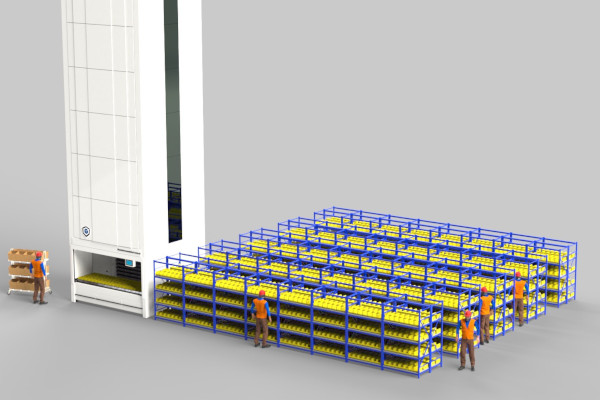

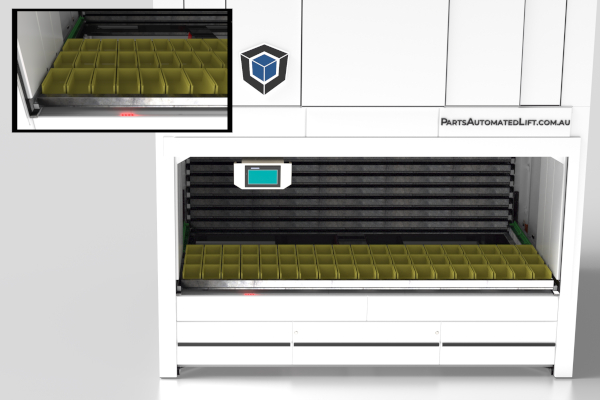

The Parts Automated Lift, or PAL, represents the latest evolution of automated storage and retrieval systems. It is designed to support a wide range of functions across various industries, ranging from manufacturing to warehousing, retail and distribution.

It’s a high-density inventory storage system for small-to-medium components, designed to help maximise floor space, minimise picking time, and enable improved productivity.

So, how does it work? The enclosed PAL unit houses a series of trays stored vertically at both the front and back. These trays can be filled with components for storage. The in-built vertical lift automatically moves the trays to a suitable location within the system.

Modular design, for your convenience

The unit is modular in design, to ensure each customer can use it for their own distinct purposes. The height of the unit can range from 2.3 metres to 12 metres, with the option to fit multiple workstations at different heights, as required.

Small Footprint & Minimal Space

Small Footprint & Minimal Space

The PAL is the ultimate space saver and helps you free up space for other important aspects of your business.

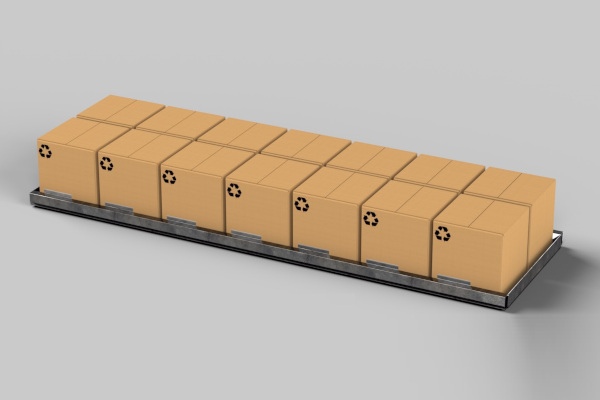

Tray Size & Weight Rating

Tray Size & Weight Rating

Each tray can carry a load of up to 700mm high with a staggering weight of up to 500kg.

Single or Multiple Workstations

Single or Multiple Workstations

With a modular construction, it's possible to have more than one workstation, where a tray gets delivered. It is even possible to have them on different floor levels if required.

Get an Estimated Quote with our Cost Calculator

100% Australian!

We are proud to have developed Australia’s first and only home-grown vertical storage and lift machine. What’s more, almost all components are made locally by trusted suppliers, meaning they’re readily available to ensure a quick turnaround and delivery.

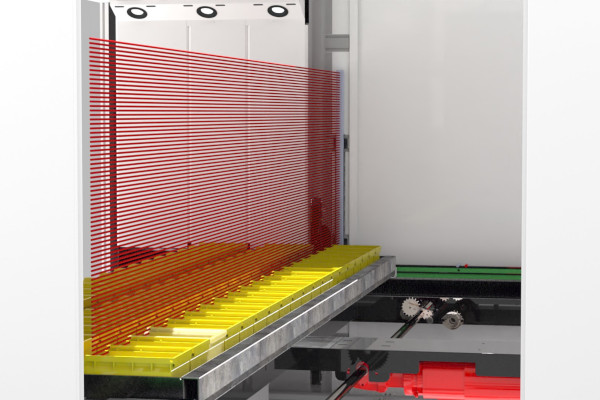

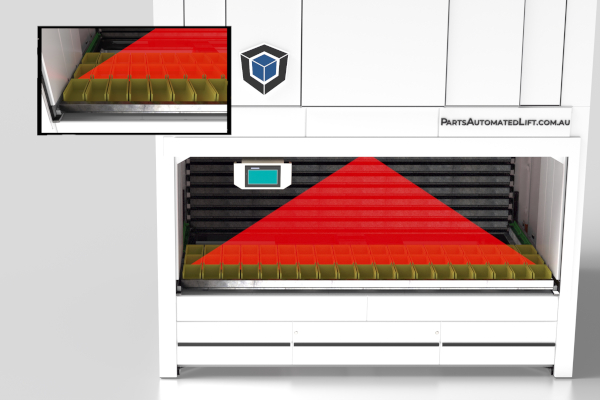

Height Sensing Optimisation

Each PAL is fitted with high-density sensor beams, which intuitively and accurately calculate the height of each tray’s load. The lift inside the machine then moves each tray to the closest appropriate storage spot, ensuring no space is wasted.

Human Machine Interface & Ergonomics

The wellbeing of your team is our number one priority. The PAL’s human machine interface, or HMI, is adjustable for ease of operation. It has been designed to optimise picking comfort. The picking height of the tray ensures no unnecessary bending or reaching is required. Rest assured, our commitment to providing the best ergonomic conditions serves to guarantee the health and safety of your workers.

‘Pick to Light’ System

A combination of LED row and laser depth indicators make it easy for workers to see where components are stored. The result of this ‘pick to light’ system is improved accuracy and the reduced potential for error. By improving efficiencies in this way you’ll boost order fulfilment performance, as well as saving time and money!

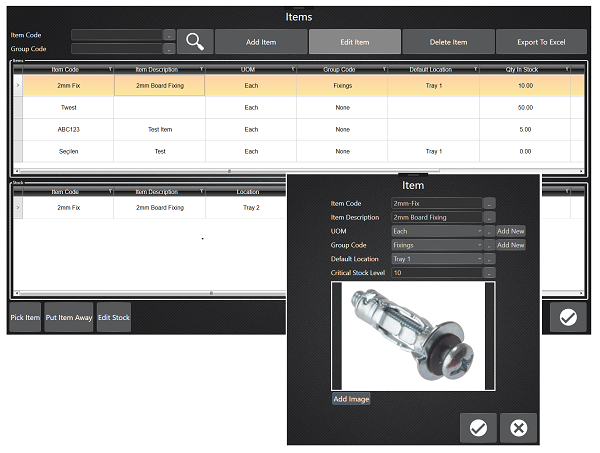

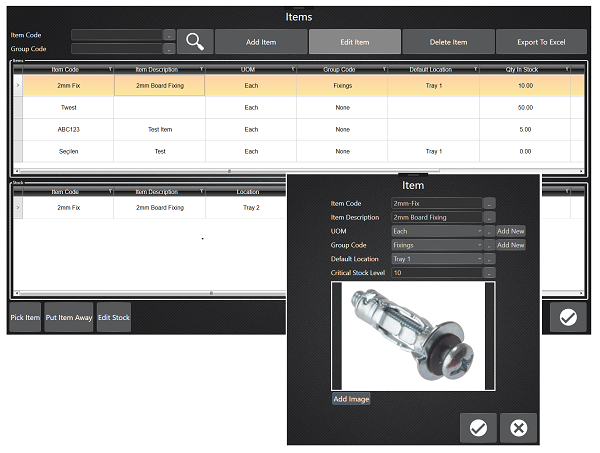

Inventory System and WMS Software

Vertical Storage Solutions has teamed up with E-max, a leading supplier of ERP software, to provide their inventory software developed especially for vertical storage machines. This inventory system can be seamlessly integrated with your current Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) software, for a fast and paperless workflow.

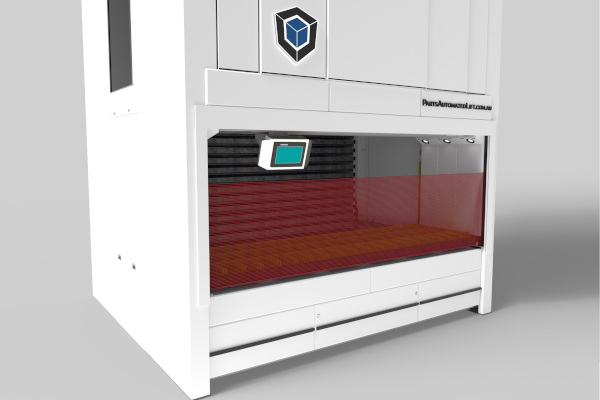

Safety, Protection & Security

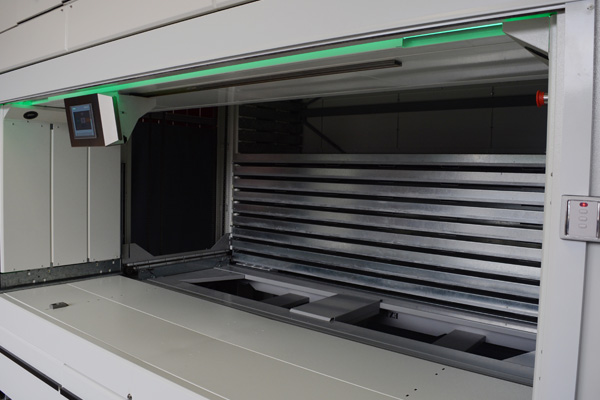

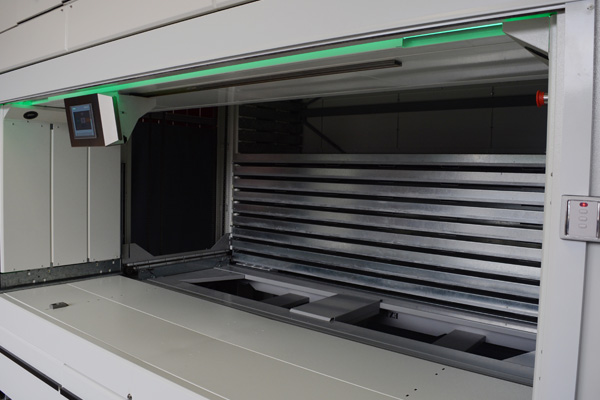

When the PAL equipment is in use, safety light curtains are activated to protect your people with ultimate precision. Whenever it’s not in use, an automated roller door protects the stored contents from dust, contaminants and theft.

Visual Safety Enhancements

To enhance safety even further a specially designed, industry-first LED indicator system lets you know the machine is safe and ready to operate. A green light illuminates the workstation when everything is running smoothly, and if one of the strict safety parameters is broken, a red light will replace the green.

Previous Customers

Main Logo Slider